- Home

- Sustainability

- Environment

- Action on Climate Change

Action on Climate Change

Basic approach

Recognizing that our business activities affect the entire planet and that protecting the global environment is essential for our survival and activity, we actively take the initiative to protect the environment under the Nisshin Seifun Group Environmental Basic Policy, including initiatives to reduce waste and CO2 emissions and to effectively use resources and energy.

We are working to minimize the effects of climate change by reducing the amount of greenhouse gases produced through our business activities, including at the manufacturing stage and during the delivery of products and services. We also recognize that climate change affects the Group’s business, and we are responding proactively so that we can fulfill our social responsibilities to ensure a stable supply of staple foods such as wheat flour and to deliver safe products through each of our businesses.

Disclosure based on TCFD recommendations

The Nisshin Seifun Group recognizes climate change as a factor that could have a direct and indirect impact across all stages of its supply chains, including the increased risk of natural disasters affecting its operating sites and wheat-growing regions. We conduct scenario analysis on climate-related risks and opportunities for our Group businesses based on the TCFD framework and use the findings as the basis for collective engagement with our stakeholders through disclosure. In August 2021, we expressed our support for the TCFD Recommendations and announced our participation in the TCFD Consortium.

We conducted scenario analyses to identify risks and opportunities for our supply chain as of 2050 in two cases: one where the effects of climate change have been effectively mitigated, and another where climate change has progressed under the Business-As-Usual (BAU) scenario. Furthermore, we have identified particularly important risks and opportunities and examined climate strategies to address them. By reflecting the results of the analysis in our business strategy, we will enhance the continuity of our business and contribute to the realization of a sustainable society.

Disclosure based on TCFD recommendations (FY2025 Version) (140.6KB)

Medium/Long-term Targets

To address global warming, in fiscal 2021 the Nisshin Seifun Group set medium/long-term targets to be achieved by fiscal 2030 and 2050. Out of the six designated greenhouse gases we have set targets for CO2 emission reductions as the highest priority in our Group operations.

Our efforts to mitigate the impacts of climate change and minimize business risks include the reduction of our CO2 emissions through the proactive introduction of energy-saving technologies and the use of renewable energy. We will continue to contribute to the realization of a decarbonized society through these and other approaches.

Targets

- Targets for 2050:

- Reduction of CO2 emissions from facilities owned by the Group to zero

- Reduction of CO2 emissions across our supply chains

* We will work toward our targets for 2030 through the same initiatives.

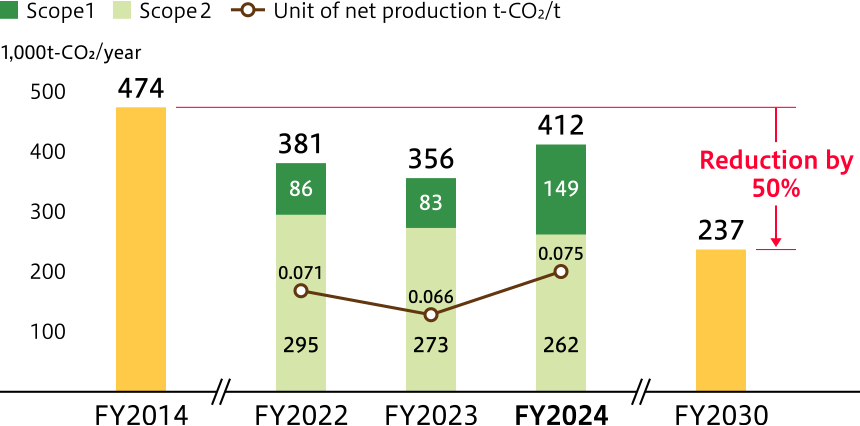

Targets for fiscal 2030: Reduction of CO2 emissions from facilities owned by the Group by 50% compared with the fiscal 2014 level

CO2 emissions volumes and intensity

We are reducing energy consumption on a Group-wide basis by installing energy-efficient facilities, improving production efficiency, and introducing renewable energy. In fiscal 2024, the total CO2 emissions for the Group increased over the previous year’s level due to the addition of Oriental Yeast India Pvt. Ltd. to the scope of calculations. We will continue to work toward the reduction of CO2 emissions across the entire Nisshin Seifun Group.

Scope (6.1MB)

| FY2014 (base year) |

FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|

| Scope1+Scope2 (1,000t-CO2) | 474 | 381 | 356 | 412 |

| Coverage (%) | 100 | 100 | 92 | 93 |

* The scope of the data does not include the operation sites of Kumamoto Flour Milling Co., Ltd., which was added to the consolidation in fiscal 2023.

Details of environmental data (6.1MB)

Toward the achievement of carbon neutrality by 2050

The Nisshin Seifun Group is actively working to reduce CO2 emissions through mitigation measures, including the introduction of energy-saving systems, and comprehensive efficiency improvement initiatives. We are also accelerating our transition to the use of renewable energy, including electricity and steam procured from renewable energy sources, and expanding our use of renewable energy.

We recognize the need for continual large-scale capital expenditure based on long-term perspectives in order to achieve our Group targets. We have formulated a roadmap for the reduction of CO2 emissions by 2030. This roadmap will allow us to visualize the timing and scale of capital expenditure and the Group-wide benefits of these investments. We have also introduced an internal carbon pricing (ICP) system as a criterion for capital expenditure decisions. We will work systematically and comprehensively to reduce energy consumption and introduce renewable energy under our roadmap for the period to 2030. We will also leverage expanded fuel transition options and potential advances in technology toward the achievement of carbon neutrality by in 2050.

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Total energy consumption (TJ) | 8,026 | 7,944 | 7,645 |

| Renewable energy consumption (TJ) | 31 | 79 | 294 |

Details of environmental data (6.1MB)

Transition to renewable energy use

Introduction of solar power generation facilities

New solar power generation facilities came online at multiple domestic and overseas business sites in the Nisshin Seifun Group. We installed facilities not only through our own investment, but also under on-site power purchase agreements (PPAs).

Number of operation sites with solar power generation facilities

Domestic: 12 sites (including 9 on-site PPAs)

Overseas: 7 business sites (including 2 on-site PPAs)

(Nisshin Seifun Welna)

(Oriental Yeast)

(Tokatsu Foods)

We have introduced a large-scale solar power generation facility at a flour plant operated by Miller Milling Company, LLC in California, an area blessed with abundant sunshine. The Fresno plant will increase the capacity of the solar power generation facility and the plant is enrolled in the ENERGY STAR Challenge for Industry*. This challenge will promote efforts to achieve further energy reduction by 2024.

* A program of the U.S. Environmental Protection Agency (EPA) to promote energy reduction through efficiency and renewable energy sources.

Procuring electricity from renewable energy sources

The Nisshin Seifun Group's domestic and overseas operation sites have made progress in purchasing electricity from renewable energy sources. In Japan, the Nisshin Seifun Group utilizes carbon-neutral options provided by electric power companies. In addition, an increasing number of overseas operation sites are using international renewable energy certificates (I-RECs) to increase the ratio of electricity purchased from renewable energy sources to 100%.

Electricity purchased from renewable sources was introduced at 13 sites, of which 11 achieved 100% usage

- Press release May 13,2024 (Japanese)

Renewable Energy Certificates (I-RECs)

- Press release August 1,2024 (Japanese)

- Press release October 10,2024 (Japanese)

100% of the electricity for operation was procured from renewable energy sources using off-site corporate PPAs schme

In November 2023, the Nisshin Seifun Tsurumi plant shift 100% of the electricity used for operation to renewable energy by aggregated solar power through off-site corporate PPAs scheme and purchasing non-fossil certificates with tracking in collaboration with electric power retailer. Virtually all of the electricity used at the Tsurumi Plant, the largest flour mill in Japan (which produces approximately one-tenth of the flour consumed in Japan), is covered with renewable energy sources that corresponding approx. 27,000 tons of CO2 emissions reductions per year.

Press release October 25, 2023 (Japanese)

Reduction of CO2 emissions through energy and electricity conservation at operation sites

Higashi-Osaka Plant (Initio Foods)

We are confident that measures such as energy conservation, power saving, and fuel switching will reduce CO2 emissions. Our commitment to the achievement of high energy efficiency includes the prioritized installation of energy-efficient equipment when building new plants or installing new facilities, and the design of production lines with layouts that ensure enhanced energy efficiency.

We will continue to make determined efforts to reduce energy and electricity consumption.

We have redesigned facilities at a prepared food plant to recover condensed water from steam drains. By returning the water, which has a temperature of around 100°C, to the water supply tank for the boiler, we can reduce the amount of water needed to replenish the tank, while also using the recovered waste heat to warm up the water in the tank. This reduces both gas consumption of the boiler and the amount of CO2 emitted.

Energy saving through lighting

We are actively implementing measures to reduce electricity consumption at each of our business sites. For example, we are installing lighting equipped with LED and motion sensors and paying close attention to how we use air conditioning to adjust temperatures in order to reduce CO2 emissions as much as possible.

Reducing CO2 emissions related to logistics

We monitor the environmental impact of transporting the Group’s products and work to reduce this impact through measures such as making packaging and containers lighter, improving truck carrying efficiency and logistics services, and making joint deliveries with other companies.

Collaborating with six other Japanese food product manufacturers to launch F-LINE®, a logistics platform for food companies

In April 2016, we collaborated with five other companies to make our first joint deliveries (non-frozen products) in the Hokkaido region. We are improving transportation efficiency through the joint use of distribution centers and delivery vehicles with the aim of reducing CO2 emissions. Our goal going forward is to continue making our logistics systems even more sustainable.

Press release July 27, 2023 (Japanese)

Managing CFCs appropriately and reducing emissions

CFC gases that are used as refrigerants in air conditioners, refrigerators, and freezers damage the ozone layer when released into the atmosphere and create a greenhouse effect that is several thousand times more potent than that of CO2. Since fiscal 2016, businesses in Japan are obligated to carry out regular inspections of these types of equipment and report leakage volumes under the Act on Rational Use and Appropriate Management of Fluorocarbons (Revised Fluorocarbon Act).

All Group business sites in Japan and overseas ensure proper management of equipment that uses these CFCs, through measures such as compiling inventories of such equipment, carrying out regular inspections, and upgrading or disposing of it when necessary. We have voluntarily set standards for carrying out this management with the aim of preventing CFC leaks.

We report any leaks involving CFC gas emissions equivalent to at least 1,000t of CO2, in accordance with the Revised Fluorocarbon Act.

Also, we are working toward switching refrigerants and upgrading equipment with CFC-free alternatives, and we are systematically investing capital to replace equipment that uses HCFCs as a refrigerant with the target of fully phasing it out by 2030.

Adapting to climate change

Global warming is posing a threat of increased damage from natural disasters including water damage from rising sea levels, tsunamis, floods, and concentrated heavy rainfall. We recognize the impact that climate change can have on the Group’s business, and we are taking various steps in response. We have the largest network of flour mills and silos in Japan which means it is our social responsibility to provide society with an uninterrupted, stable supply of foods. We work to minimize the impact of disasters on people’s livelihoods by carrying out measures to ensure food supply is maintained, such as improving management structures and operating facilities.

The Paris Agreement and UN Sustainable Development Goals (SDGs) agreed in 2015 are accelerating a shift in society toward sustainable development. In order to remain as a Group that is truly essential to society, we need to adapt to the various risks posed by climate change more than ever before. We acknowledge that such action takes time, so we are aiming to integrate environmental management more firmly into our business with the long-term focuses of 2030 and 2050.

Minimizing impact on business

We are implementing measures to minimize the impact on consumers in the event of a disaster by ensuring a steady supply of foods.

In the event that changes in rainfall patterns due to unusual climate conditions cause concerns of potential droughts, we will assess the state of water resources at manufacturing sites and potential impact on supply structures, and take steps to minimize the impact on production.

We are also implementing measures focused on preventing water damage caused by disasters at business sites across Japan. We have used the results of hazard map analysis to predict the impact of floods and tsunamis on 25 business sites and we are ensuring that these sites are ready to act in an emergency by creating countermeasure manuals, procedure sheets, and carrying out training drills.

- Preparing for emergencies

-

- Analyzing the impact of natural disasters using hazard maps

- Creating countermeasure manuals and procedure sheets for times of disaster

- Carrying out regular training in preparation for emergency situations

- Positioning key manufacturing equipment on the second floor of buildings or higher

- Installing generators in preparation for power outages during disasters

At our Tsurumi Plant, which is Japan’s largest flour mill, we are minimizing a potential collapse of the wharf or other damage from berthing ships transporting flour through steps such as reinforcing the foundations of the wharf and its surrounding area. We have also formulated a business continuity plan to fulfill the Group’s social responsibility of maintaining food supplies that are essential for society. While our efforts have been primarily focused on responding to tsunamis resulting from earthquakes, we also recognize that they will prove useful in tackling climate change-related risk to ensure stable food supplies.

Introducing heat reflective materials for buildings

Nisshin Seifun Group Inc.’s Kamifukuoka Laboratories

One of the effects of global warming is an increase in the number of extremely hot days during summer. By introducing heat reflecting materials on the roofs and exteriors of the buildings, we are realizing the effective use of air conditioning facilities.

Survey of literature relating to the impact of climate change on wheat

There are concerns that rising global temperatures, extreme weather events, and changes in rainfall patterns will affect the growth of crops, increase damage caused by pests and diseases, and reduce production volume and quality.

The Nisshin Flour Milling Group will continue to research the impact of climate change on wheat growth and flour quality.

Survey of literature relating to the impact of climate change on wheat (539KB)