- Home

- Sustainability

- Environment

- Waste Reduction and Resource Recycling

Waste Reduction and Resource Recycling

Basic approach

ecognizing that our business activities affect the entire planet and that protecting the global environment is essential for our survival and activity, we actively take the initiative to protect the environment under the Nisshin Seifun Group Environmental Basic Policy, including initiatives to reduce waste and CO2 emissions and to effectively use resources and energy.

Initiatives toward realizing a recycling based society and circular economy

The Group is working toward forming a resource recycling society by using resources effectively. In fiscal 2021, we achieved our target of zero production waste for both the entire Group and for each individual business site. Going forward, we will continue to promote the effective use of resources on a Group-wide basis by striving to cut down as much waste as possible from production processes and to reduce the amount of packaging materials used on our products. We also maintain zero production waste for both the entire Group and for each individual business site in Japan.

Medium/Long-term Targets

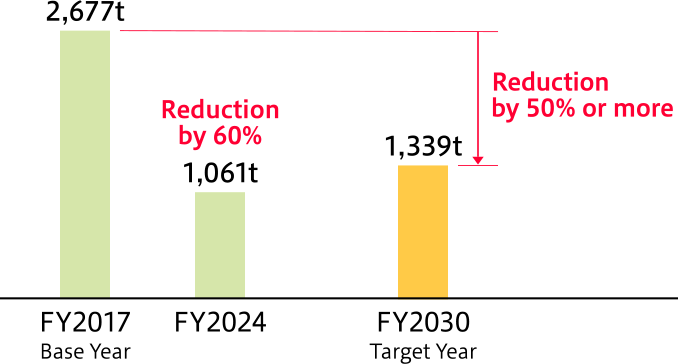

In fiscal 2021, the Nisshin Seifun Group set medium-term targets to be achieved by fiscal 2030.

Reducing food waste

We will work with our supply chain partners to reduce food waste and contribute to realizing the sustainable food systems.

- Targets for fiscal 2030:

- Reduction of food waste, from the procurement of raw materials to the delivery of products to customers, by 50% or more compared with the fiscal 2017 level * This target applies to group companies in Japan. The targets for Initio Foods Inc., Joyous Foods Co., Ltd., and Tokatsu Foods Co., Ltd. are relative to fiscal 2020 levels.

- We will work with our partners to reduce food waste at all supply chain stages

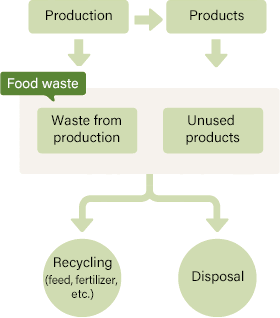

The Nisshin Seifun Group defines food waste as by-products and waste products from food manufacturing and distribution processes that cannot be used in food and are processed and disposed of through thermal recycling, landfill disposal, incineration, and other means. Business-related waste and by-products used in animal feed, fertilizers and other products are not included in “food waste” because they result in sustainable recycling.

Proactive initiatives in the period to fiscal 2024 resulted in the achievement of our medium- to long-term targets ahead of schedule. We will continue our efforts to achieve even greater reductions in food waste in the future.

Reduction of food waste (Group companies in Japan)

- Note1: Food waste: defined as by-products and waste products from food manufacturing and distribution processes that cannot be used in food and are processed and disposed of through thermal recycling, landfill disposal, incineration, and other means.

- Note2: The base year for group companies in Japan is fiscal 2017.

Reducing packaging waste

The Nisshin Seifun Group will reduce the amount of fossil fuel-derived plastics used in containers and packaging. We will also contribute to plastic recycling.

- Targets for fiscal 2030:

- Reduction of the amount of fossil fuel-derived plastics used by at least 25% compared with the fiscal 2020 level * This target applies to group companies in Japan.

- Promotion of plastic recycling, such as through the use of environmentally-friendly designs

- Increased use of sustainable packaging materials, such as biomass plastics, recycled plastics, recycled paper, and FSC-certified paper

Various types of containers and packaging are used for products manufactured by Nisshin Seifun Group. Because these materials play an important role in maintaining the quality of food products until they are used by consumers, safety and reliability will remain key requirements as we move toward the use of environmentally-friendly designs and sustainable packaging materials.

In fiscal 2024, we revised the scope of calculations retroactively back to the base year, with the result that the total of amount of plastic used by the Group increased from 5,529 tons to 5,997 tons. We are aware that increased efforts will be needed to reduce plastic use by the target year, and we will continue our efforts to cut the amount of fossil fuel-derived plastics used.

Reduction of packaging waste

Amount of fossil fuel-derived plastics used in containers and packaging used by group companies in Japan

Waste volumes and resource use

We managed to control the amount of waste produced through efforts such as managing production in line with the balance of supply and demand and improving product storage and shipping methods. We also focused on recycling and upcycling resources effectively, including using waste as a raw material for fertilizers and feedstuffs.

The recycling rate for the entire group in Japan has been maintained at 99.9% since FY2016, and we have also achieved zero emissions on a business unit basis since FY2019 We are continuously working toward our annual goal of keeping the zero emissions we have achieved since FY2021. We will continue to work on the 3Rs (reduce, reuse, and recycle) and promote effective use of resources.

Group total volume of final disposal waste (landfill)

* Excludes overseas subsidiaries

Details of environmental data (6.1MB)

Recycling food resources

In fiscal 2021, we were able to recycle 99.8% of food waste.

Food resource materials flow

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Food waste generated (thousand t) |

34 | 44 | 50 |

| Recycling rate (%) | 99.8 | 99.8 | 99.8 |

Scope (6.1MB) * Excludes overseas subsidiaries

Contributing to industrial ecology

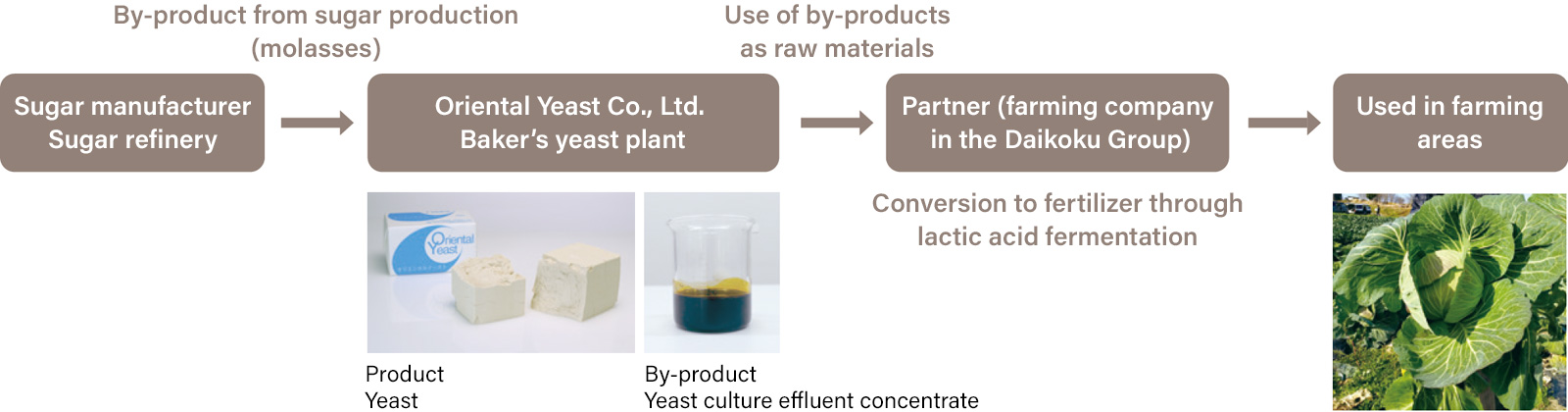

Use of manufacturing by-products as a cultivation medium for crops

Oriental Yeast Co., Ltd. (OYC) uses molasses during yeast production. Molasses is a by-product of a sugar industry and is produced after the extraction of sugarcane. As an initiative to utilize the by-product produced after yeast production called as Yeast culture effluent concentrate, OYC have partnered with a farming company to apply this Yeast culture effluent concentrate for a crop growing medium. Reports indicate that this method helps to restore the soil composition and encourages strong root growth, resulting in higher yields and crops with enhanced flavors, compared to conventional growing methods based on chemical fertilizers. In addition to the potential for regenerative agriculture without the use of chemical fertilizers, this approach can also be used to create a recycling loop for food waste and residues generated from the food industry.

|

Reducing and reusing containers and packaging

We are actively promoting 3R (reduce, reuse, recycle) activities in order to reduce the amount of container and packaging materials we use. This includes designing containers and packaging in a way that minimizes environmental impact while still ensuring product safety. We also have a contract with the Japan Containers and Packaging Recycling Association under which the containers and packaging containing the Group’s products are recycled after use in exchange for recycling fees in accordance with the quantity of containers and packaging produced.

Managing chemical substances appropriately

The handling of chemical substances at the Group’s business sites is managed thoroughly in accordance with the Group’s standards which cover everything from storage and use to disposal. We also carry out audits to ensure compliance with laws, regulations, and the Group’s management standards. For specific chemical substances which require special care under the Pollutant Release and Transfer Register Act, we monitor emission and transfer volumes and work to curb any discharges into the environment.

The Group’s atmospheric emissions and substance transfer volumes, including waste, for the last three years are as follows. There were no emissions affecting soil or marine environments.

| FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|

| Total chemical substance emissions (t) | 8.7 | 5.3 | 3.8 | |

| Breakdown | Atmospheric emissions (t) | 0.70 | 0.38 | 0.16 |

| Emissions into public waterways (rivers, lakes, seas) (t) |

0 | 0 | 0 | |

| Transfer to the sewer (t) | 0 | 0 | 1.9 | |

| Quantities of chemicals included in waste products transferred out of facilities (t) | 8.0 | 5.0 | 1.7 | |

Scope (6.1MB) * Excludes overseas subsidiaries

Managing PCB waste

We thoroughly manage machinery containing polychlorinated biphenyls (PCB) that we have used in the past in compliance with laws and regulations. We have completed the disposal of these substances in accordance with relevant legislation, such as the PCB Special Measures Act.

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| PCB disposal (t) | 0 | 0 | 0 |

Scope (6.1MB)

Appropriate waste disposal management and preventing illicit resale

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Number of site visits | 111 | 157 | 195 |

Scope (6.1MB) * Excludes overseas subsidiaries

We strive to ensure that waste from each Group business site is disposed of properly in accordance with our own management standards and we audit our contractors, to confirm compliance with set methods and management practices.

When outsourcing waste disposal and recycling, we assess all contractors through site visits before agreeing a contract and carry out regular assessments every two years for businesses already under contract.

We make sure to remove packaging from product waste and have employees witness disposal procedures in order to prevent illicit resale.

If the contractor does not meet our standards, we will provide guidance and advice to them for improvement or discontinue the contract as a result of these evaluation.

Also, when selecting disposal contractors, we prioritize effective resource reuse and recycling as much as possible.

Preventing soil pollution

When selling, purchasing, or leasing land, we disclose information in a proper manner. We also investigate the state of soil pollution and take appropriate measures when necessary.