- Home

- Sustainability

- Environment

- Water Resource Initiatives

Water Resource Initiatives

Basic approach

Recognizing that our business activities affect the entire planet and that protecting the global environment is essential for our survival and activity, we actively take the initiative to protect the environment under the Nisshin Seifun Group Environmental Basic Policy, including initiatives to reduce waste and CO2 emissions and to effectively use resources and energy.

Water management

We recognize that our business activities are very closely linked to water resources, so we are carrying out initiatives aimed at using these resources effectively, as well as risk assessments.

Within our business activities, the volume of water used in the flour milling business is relatively low, but a certain amount of water is needed for the processed foods business, and prepared foods and other prepared foods business. We are conscious of this issue and under our Environmental Basic Policy, we promote environmental protection such as using water resources effectively, reducing water use volumes, and preventing water pollution.

Medium/Long-term Targets

To address against future water resource shortages, in fiscal 2021 the Nisshin Seifun Group set medium-term targets to be achieved by fiscal 2040. We work for reducing water consumption in our production processes by identifying locations and processes where water can be reduced throughout our group and by reviewing water usage methods.We will also work with our partners at all stages of our supply chain to ensure effective utilization of this finite resource.

Targets

- Target for fiscal 2040:

- Reduction of the amount of water used in plants per unit of production by 30% compared with the fiscal 2022 level

- * This target applies to group companies in Japan and overseas.

- * We have set targets for each region based on the water supply risk level. We aim to halve the amounts of water used in regions with particularly high water risk levels.

| FY2022 | FY2023 | FY2024 | FY2041 (Target year) |

|---|---|---|---|

| 1.14 | 1.09 | 1.05 | 0.86 |

* Specific water withdrawal: Excluding the water that unable to reduce such as by incorporated into products

Overview of water use

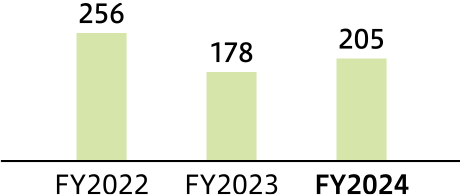

We have major production sites in eleven countries, and we monitor the water use volumes and effluent drainage routes of all manufacturing sites in line with Group management standards. In addition to the daily management of water conservation and leakage prevention, we are also working to reduce water use and wastewater per production unit through initiatives such as concentrating production into highly efficient production lines, adjusting our product mix, and carefully planning production. Going forward, we will set targets using appropriate indicators for our Group’s operations in order to making water usage even more effective.

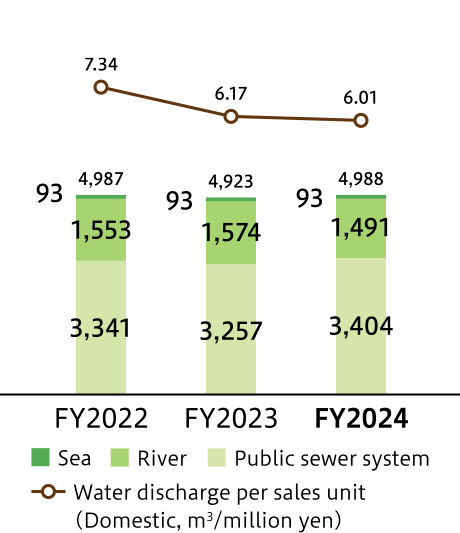

Water use and effluent load

In our flour milling business, we mainly use a dry milling process which uses an extremely small amount of water relative to production volumes.

All our businesses are equipped with wastewater treatment facilities, and we work to perform appropriate management that uses water as effectively as possible.

We will continue to prioritize circular water use and the use of recycled water.

Details of environmental data (6.1MB)

Taking care with water resource

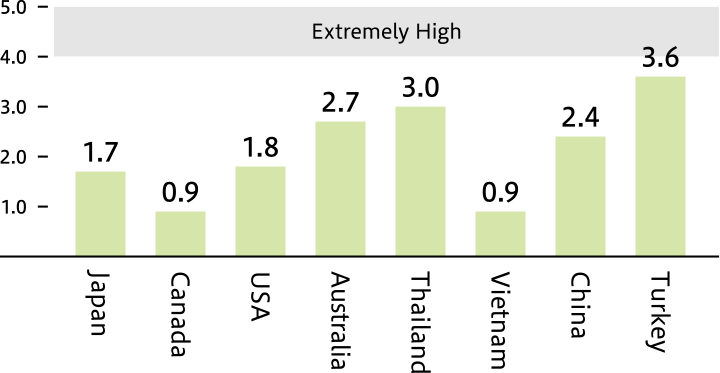

Since fiscal 2018, we have been using Aqueduct, an evaluation tool developed by the World Resources Institute, to regularly evaluate water stress and water risk at all manufacturing sites in Japan and overseas and in the regions from which we source raw materials.

Scope of evaluations

Primary raw material sourcing regions: Sourcing regions in eight countries including Japan

Group manufacturing sites: 54 in Japan and 34 overseas*

* As of the end of March, 2021

Carrying out water risk evaluations

The results of water risk evaluations have shown that none of our raw material sourcing regions are at extremely high risk. In order to achieve safe and secure procurement, we conduct supplier evaluations based on our own Group standards and maintain regular communication with business partners, including through site inspections.

At our manufacturing sites in China, which have a relatively high level of water risk compared to sites in other countries, we have found that water stress levels are high. As our production at these sites does not require large volumes of water, this is not a major concern at present, but we monitor water use at each site and strive to reduce per unit water use at sites where it is particularly high.

- Water stress: A situation where the demand for water exceeds the available amount during a certain period or where poor quality restricts its use.

Referenced Aqueduct 3.0 (2019)

| Group-wide | Areas with high water stress | |

|---|---|---|

| Number of production sites | 87 sites in 11 countries | 5 sites in 3 countries |

| Water resource input | 6,860 thousound m3 | 37,000 m3 |

- Note 1: Countries with Nisshin Seifun Group production sites: Australia, Canada, China, Indonesia, Japan, New Zealand, Thailand, Turkey, the United States, Vietnam, India

- Note 2: Countries with high water stress levels: Australia, China, the United States

- Note 3: Areas with high water stress are defined as locations in which the water stress is listed as “Extremely High” in Aqueduct (WRI)

- Note 4: The scope of the data does not include the operation sites of Kumamoto Flour Milling Co., Ltd. and its affiliates

- Referenced Aqueduct 3.0 (2019)

Using water resources effectively

We are working to save water by reducing water consumption, raising awareness among employees, and cultivating water-saving mindsets through environmental education. Also, when we need to dispose of wastewater, we strive to effectively use water resources by disposing of this water in ways that minimize environmental impact.

Installation of water resource reuse system

water resource reuse system

Oriental Yeast Co., Ltd. has installed a system at its Tokyo Plant to recover water resources that were previously released into the wastewater system. The water is processed in a water treatment system that restores it to the same quality as tap water, allowing it to be reused in the plant. This system will reduce the amount of water resources used in yeast production by around 60%.

Wastewater treatment equipment that generates clean energy

Wastewater treatment equipment installed at Oriental Yeast Co., Ltd.’s Osaka Plant combines methane fermentation with activated sludge treatment. This wastewater treatment process creates methane gas that can be used as fuel for a biogas engine that generates electricity, thereby reducing the amount of energy consumed by the plant. Furthermore, the sludge produced by this process is used as a fertilizer. This both minimizes the environmental impact of wastewater treatment and reduces the plant’s energy consumption.

Protecting water resources

Supporting activities to protect Kiritappu Wetland

Our business and products are dependent on the blessings of nature. We hope that these blessings will continue to be available as a foundation of a healthy and fruitful life for people into the future, so we are supporting activities of the authorized NPO Kiritappu Wetland National Trust, which is working to conserve Kiritappu Wetland in Hokkaido. Kiritappu Wetland is Japan’s third biggest wetland and the trust carries out research activities to understand this abundant ecosystem and its connections to the surrounding area, as well as conserve the upstream areas that provide the wetland with water and the surrounding forest.

Local activities to protect spring water (NBC Meshtec Inc.)

There are many natural springs in the region surrounding NBC Meshtec Inc.’s head office. The annual average discharge of these abundant springs is 14.5 liters per second, thereby providing a habitat for species that can only flourish in fresh streams, such as Japanese freshwater crabs and Semisulcospira Libertina freshwater snails. It is also an important recreational area for the region, where fireflies can be found at the start of summer.

Since its founding, NBC Meshtec has sought to operate its business in a way that can coexist with the bountiful nature of the Musashino area, so NBC Meshtec Inc. works with local communities on activities to preserve these water resources.